2018 China New Design Conductor Material And Heating Application Silicone Wire - spray painting machine for glasses – FOD Electrical Eng

2018 China New Design Conductor Material And Heating Application Silicone Wire - spray painting machine for glasses – FOD Electrical Eng Detail:

- Place of Origin:

- Guangdong, China (Mainland)

- Brand Name:

- FOD

- Model Number:

- F-IM002

- Condition:

- New

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Name:

- Sunglasses Frame,plastic parts Spray Painting Machine (F813OM806

- Dimention:

- 2160mm*1580mm*2640mm

- Clolor:

- Gray/ Yellow

- Brand:

- FOD

- Wight:

- 170KG

- Model:

- Reciprocate model

- HS Code:

- 8424899910

Packaging & Delivery

- Packaging Details

- export standard package

- Delivery Time

- 15days

spray painting machine for glasses

| 1,Dimensions(L*W*H) | 2.16m*1.58m*2.64m |

| 2,In put | 380V,50HZ |

| 3,Output Power | 5KW |

| 4,Max Spraying Area | Max 150mm*150mm |

| 5,No. Spray Gun | 1PCS |

| 6,Max No.of Work piece | 10PCS |

| 7,Speed | adjustable |

| 8,Control Panel | PLC touch screen |

| 9,Material | Stainless Steel |

| 10,Spraying type | reciprocating |

Advantage Specifications spray machine:

This spray painting machine for glasses is especially popular in sunglasses painting industry and Photo frame painting industries, machine is designed with intelligent servo system and controlled by PLC. Customer can easily adjust different angle from different products to get a perfect painting effect.

1. With Panasonic servo precision system. It helps solve angle painting problem.

2. With DEVILBISS air spray gun ensure Good quality painting.

3. With Panasonic PLC control system ensure easy operation. Operator can set programming painting data by touch screen.PLC with memory functions for each product setting data to same product again production. Operator could start production directly and no need set once more.

Maintenance period:

One year warranty will be provided on the condition of normal operation of the machine. During the period of warranty, damaged parts could be exchanged at free if the damaged is owing to bad quality of the goods, Damaged parts is required to return us. If it was damaged by human being, parts will be exchanged or repaired at cost as quotation.

Shipping

1.Deliery within 20working days.

2.FOB Shenzhen or CIF sea shipping.

3.Wooden case package avoiding damage

Our supply Scope

1.We manufactory kinds of Automatic spray painting machine including.

2.Rotation type auto painting machine for outside surface.

3.Rotation type and reciprocating type inner spray automatic painting machine.

4.Reciprocating type XY axis,3axis,4axis,5 axis,6axis,7aixs coating machine.

5.Robert series spray coating system;

6.Up-Down lift type powder coating equipment.

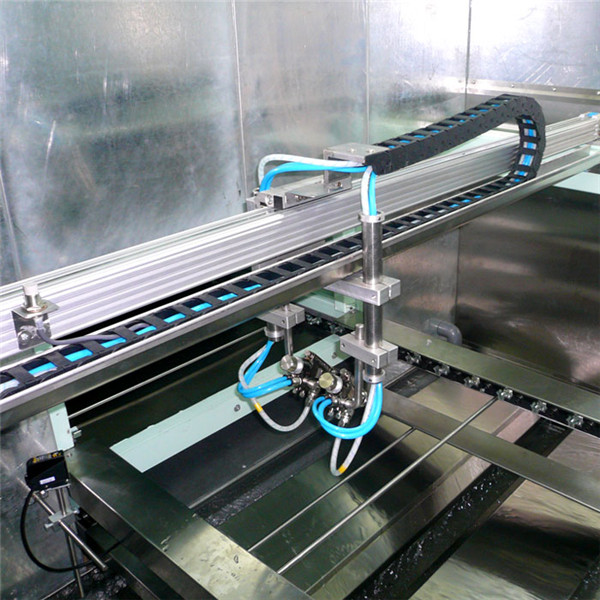

Machine show

Kindly remind:Above photoes are for custemer reference only.Final design could be adjustated as per customer’s prodcuts.

Product detail pictures:

Related Product Guide:

Top Tips on Using a Spray Painting Machine

Need of Powder Coating Equipment

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for 2018 China New Design Conductor Material And Heating Application Silicone Wire - spray painting machine for glasses – FOD Electrical Eng , The product will supply to all over the world, such as: Melbourne, Czech, Honduras, Our solutions are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!