Lowest Price for Lime Powder Production Plant - Factory wholesale price Five Axis reciprocating spray painting machine for PU paint – FOD Electrical Eng

Lowest Price for Lime Powder Production Plant - Factory wholesale price Five Axis reciprocating spray painting machine for PU paint – FOD Electrical Eng Detail:

- Condition:

- New

- Type:

- Coating Production Line

- Substrate:

- Steel

- Coating:

- Painting

- Place of Origin:

- Guangdong, China (Mainland)

- Brand Name:

- FOD

- Model Number:

- F813AM005

- Voltage:

- 220V

- Power(W):

- 600W

- Dimension(L*W*H):

- (W)1500mmx(D)1200mmX(H)1800mm

- Weight:

- 320KG

- Certification:

- CE ISO9001

- Warranty:

- 1 Year

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Used for:

- automatic UV &PU coating

- Machine clolor:

- Gray

- Dimention:

- (W)1500mmx(D)1200mmX(H)1800mm

- Input:

- 110V/120V/127V/220V/240V/380V/415V/460V,50HZ/60HZ

- Output:

- 600W

- Main material:

- 50*50 square pipe steel and stainless steel

- Main control:

- PLC Touch Screen system

- Hs Code:

- 8424899910

- Port:

- Shenzhen

- Use:

- Car auto parts painting, Photo frame painting, TV frame painting

Packaging & Delivery

- Packaging Details

- Export standard package

- Delivery Time

- 15days

1. Five Axis reciprocating spray painting machine Brief

We specialized in manufacturing different type of axis automatic spray painting system covering single axis reciprocating spray painting system, X-Y axis spray painting system, Three, Four and Five axis spray painting system. The technology is widely applied in various industries such as toy, electronics ,vacuum plating, wood door panel, automotive parts and plastic parts.

2. Five Axis reciprocating spray painting machine Main advantage

The axis spray painting system designed on basis of servo reciprocating and R,T and Z axis. It provides stable and balanced painting surface treatment, especially the spray fluid, atomization, angle and distance is very flexible adjusted as per the product,

It can be easily operated by one worker and the spraying parameters can be fast saved in PLC memory card .Our axis spray painting equipment has been in hot popular since in market. It helps modern company saves much labor cost and increases production capacity.

3. Five Axis reciprocating spray painting system Technical Parameter

| 1,In put | 110V/120V/127V/220V/240V/380V/415V/460V,50HZ/60HZ |

| 2,Output Power | 600W |

| 3,Max Spraying Area | Max dia.50mm |

| 4,No. Spray Gun | 1PCS |

| 5,Max No.of Work piece | 4-120PCS |

| 6,Speed | (adjustable) |

| 7,Spay coating type | reciprocating 5 axis painting machine servo system |

| 8,Control Panel | PLC touch screen |

| 9,Dimensions(L*W*H) | 1500mm*1200mm*1800mm |

| 10,Main Material | stainless steel &steel |

| 11, X*Y*Z travel area | 850(X)*850(Y)*300(Z) |

| 12,Widely Application | Laptop, display, LCD TV,Cellphone,MP3,Button,Desk computer Keyboard, Portable hard drive, Plastic ball, Car spare parts, Photo Frame, Tablet computer pad |

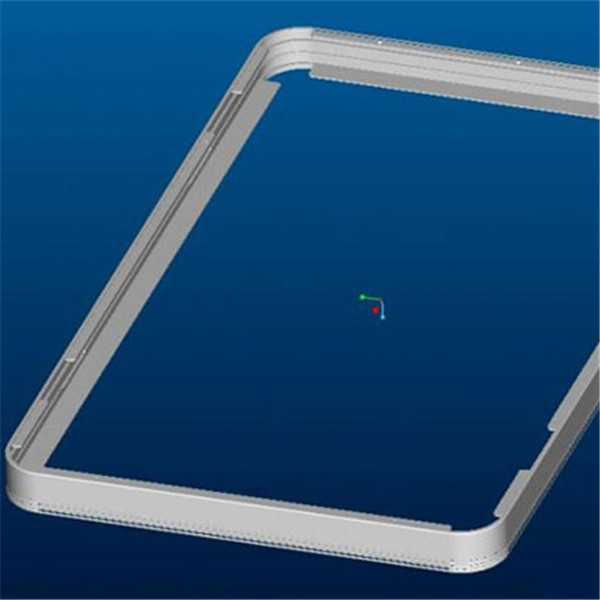

4. Five Axis reciprocating spray painting machine Picture Show

Infront View

5. Fast one-step Packing& delivery

10 days disptach the machine since customer placed oder.

6. Installation service

Engineer workers are available to make 20days installation and 5days testing production at customer’s factory based on final contract design drawing. Kindly note that for overseas installation,

7. Maintenance Warranty:

One year warranty will be provided on the condition of normal operation of the machine. During the period of warranty, damaged parts could be exchanged at free if the damaged is owing to bad quality of the goods, Damaged parts is required to return

8. Contact us for the latest price of Five Axis reciprocating spray painting machine

Product detail pictures:

Related Product Guide:

Industrial Conveyor Systems Are A Part Of All Industries

Top Tips on Using a Spray Painting Machine

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for Lowest Price for Lime Powder Production Plant - Factory wholesale price Five Axis reciprocating spray painting machine for PU paint – FOD Electrical Eng , The product will supply to all over the world, such as: Roman, Comoros, Manila, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

A good manufacturers, we have cooperated twice, good quality and good service attitude.