Massive Selection for Alaluminium Extrusion Plant - Five axis reciprocating paint spraying system for plastic frame shell – FOD Electrical Eng

Massive Selection for Alaluminium Extrusion Plant - Five axis reciprocating paint spraying system for plastic frame shell – FOD Electrical Eng Detail:

- Condition:

- New

- Type:

- Other

- Substrate:

- Plastic,ABS parts,Metal parts

- Coating:

- Painting

- Place of Origin:

- Guangdong, China (Mainland)

- Brand Name:

- FOD

- Model Number:

- Faxis-5

- Voltage:

- 380V/220v50HZ

- Power(W):

- 600w

- Dimension(L*W*H):

- L1500mm*W1200mm*H1800mm

- Weight:

- 320KG

- Certification:

- CE ISO9001

- Warranty:

- 12 Months

- After-sales Service Provided:

- Engineers available to service machinery overseas

Packaging & Delivery

- Delivery Time

- 10 days

1. Five Axis reciprocating paint spraying system Brief

We specialized in manufacturing different type of axis automatic spray painting system covering single axis reciprocating spray painting system, X-Y axis spray painting system, Three, Four and Five axis spray painting system. The technology is widely applied in various industries such as toy, electronics ,vacuum plating, wood door panel, automotive parts and plastic parts.

2. Five Axis reciprocating paint spraying system Main advantage

The axis spray painting system designed on basis of servo reciprocating and R,T and Z axis. It provides stable and balanced painting surface treatment, especially the spray fluid, atomization, angle and distance is very flexible adjusted as per the product,

It can be easily operated by one worker and the spraying parameters can be fast saved in PLC memory card .Our axis spray painting equipment has been in hot popular since in market. It helps modern company saves much labor cost and increases production capacity.

3. Five Axis reciprocating paint spraying system Technical Parameter

| ,In put | 220V,50HZ |

| 2,Output Power | 600W |

| 3,Max Spraying Area | Max dia.50mm |

| 4,No. Spray Gun | 1PCS |

| 5,Max No.of Work piece | 4-120PCS |

| 6,Speed | (adjustable) |

| 7,Spay coating type | reciprocating 5 axis painting machine servo system |

| 8,Control Panel | PLC touch screen |

| 9,Dimensions(L*W*H) | 1500mm*1200mm*1800mm |

| 10,Main Material | stainless steel &steel |

| 11, X*Y*Z travel area | 850(X)*850(Y)*300(Z) |

| 12,Widely Application | Laptop, display, LCD TV,Cellphone,MP3,Button,Desk computer Keyboard, Portable hard drive, Plastic ball, Car spare parts, Photo Frame, Tablet computer pad |

.4. Five A

.4. Five A

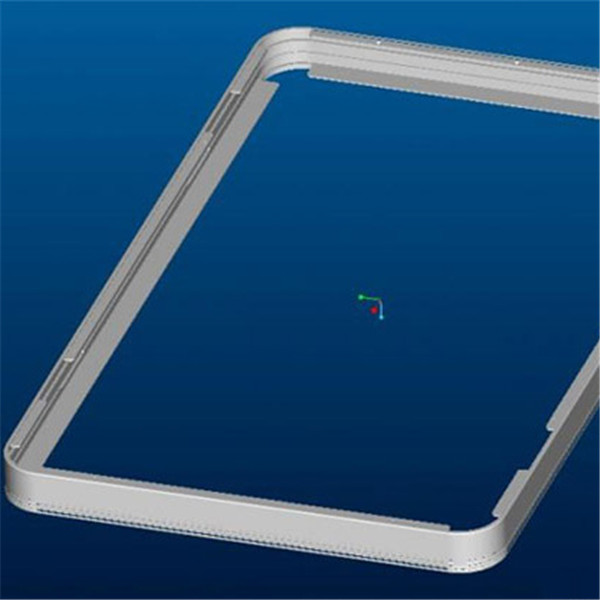

Product detail pictures:

Related Product Guide:

Industrial Conveyor Systems Are A Part Of All Industries

Top Tips on Using a Spray Painting Machine

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Massive Selection for Alaluminium Extrusion Plant - Five axis reciprocating paint spraying system for plastic frame shell – FOD Electrical Eng , The product will supply to all over the world, such as: Belgium, Denmark, Amsterdam, So far our merchandise have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have now 13years experienced sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to provide our customers with high quality items and excellent service.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!