Massive Selection for Alaluminium Extrusion Plant - Five axis reciprocating paint spraying system for plastic frame shell – FOD Electrical Eng

Massive Selection for Alaluminium Extrusion Plant - Five axis reciprocating paint spraying system for plastic frame shell – FOD Electrical Eng Detail:

- Condition:

- New

- Type:

- Other

- Substrate:

- Plastic,ABS parts,Metal parts

- Coating:

- Painting

- Place of Origin:

- Guangdong, China (Mainland)

- Brand Name:

- FOD

- Model Number:

- Faxis-5

- Voltage:

- 380V/220v50HZ

- Power(W):

- 600w

- Dimension(L*W*H):

- L1500mm*W1200mm*H1800mm

- Weight:

- 320KG

- Certification:

- CE ISO9001

- Warranty:

- 12 Months

- After-sales Service Provided:

- Engineers available to service machinery overseas

Packaging & Delivery

- Delivery Time

- 10 days

1. Five Axis reciprocating paint spraying system Brief

We specialized in manufacturing different type of axis automatic spray painting system covering single axis reciprocating spray painting system, X-Y axis spray painting system, Three, Four and Five axis spray painting system. The technology is widely applied in various industries such as toy, electronics ,vacuum plating, wood door panel, automotive parts and plastic parts.

2. Five Axis reciprocating paint spraying system Main advantage

The axis spray painting system designed on basis of servo reciprocating and R,T and Z axis. It provides stable and balanced painting surface treatment, especially the spray fluid, atomization, angle and distance is very flexible adjusted as per the product,

It can be easily operated by one worker and the spraying parameters can be fast saved in PLC memory card .Our axis spray painting equipment has been in hot popular since in market. It helps modern company saves much labor cost and increases production capacity.

3. Five Axis reciprocating paint spraying system Technical Parameter

| ,In put | 220V,50HZ |

| 2,Output Power | 600W |

| 3,Max Spraying Area | Max dia.50mm |

| 4,No. Spray Gun | 1PCS |

| 5,Max No.of Work piece | 4-120PCS |

| 6,Speed | (adjustable) |

| 7,Spay coating type | reciprocating 5 axis painting machine servo system |

| 8,Control Panel | PLC touch screen |

| 9,Dimensions(L*W*H) | 1500mm*1200mm*1800mm |

| 10,Main Material | stainless steel &steel |

| 11, X*Y*Z travel area | 850(X)*850(Y)*300(Z) |

| 12,Widely Application | Laptop, display, LCD TV,Cellphone,MP3,Button,Desk computer Keyboard, Portable hard drive, Plastic ball, Car spare parts, Photo Frame, Tablet computer pad |

.4. Five A

.4. Five A

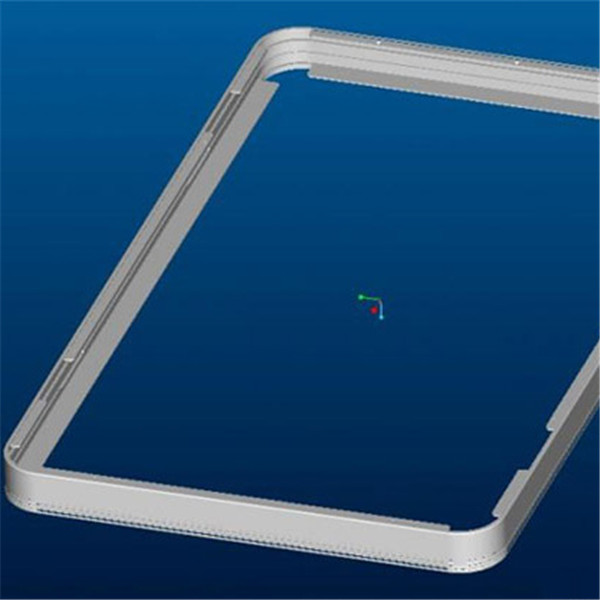

Product detail pictures:

Related Product Guide:

Top Tips on Using a Spray Painting Machine

Using Conveyor Systems

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for Massive Selection for Alaluminium Extrusion Plant - Five axis reciprocating paint spraying system for plastic frame shell – FOD Electrical Eng , The product will supply to all over the world, such as: United Kingdom, Hyderabad, Jeddah, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to supply the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!