Special Design for Frozen French Fries Production Line - Five year mainternance Robotic spray painting line for OU paint,UV paint spraying – FOD Electrical Eng

Special Design for Frozen French Fries Production Line - Five year mainternance Robotic spray painting line for OU paint,UV paint spraying – FOD Electrical Eng Detail:

- Type:

- Automatic Control

- Other:

- Intellegent Spraying Robot

- Application:

- Industrial Automaticspray painting

- Spraying method:

- On-line Traking Spraying

- Automatic Grade:

- Fully Automatic

- Spray gun:

- Devilbiss/Graco

- Spraying for:

- lacquer paint,PU,UV paint finishing

Packaging & Delivery

- Packaging Details

- Film and wooden case

- Delivery Time

- 20days

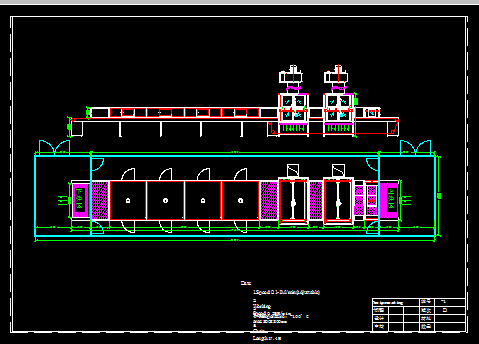

1.Robotic spray painting line Brief

Automatic Robotic spray painting line which support one-step automatic painting production including: Loading—Antistatic dust-free—Robot spray system —Flash off—Top coat——Paint drying—-UV curing—-cooling—Unloading. It’s also widely used together with Vacuum metallization treatment to provide high quality surface treatment for Plastic toys, Car spare parts, frames parts, Motorbike spare controller, Tablet computer pad shell, Clock frame, Wood door panel.

2..Robotic spray painting line Main Advantage

2.1. More flexible spray angles and distance

2.2 Designed as per customers requirement

2.3 Robot high spray rate

2.4 Core technology support

2.5 high quality guarantee

2.6 less maintenance

2.7 various materials such as plastic, metal and wood industries

2.8 full automatic controlled by PLC touch screen

3. Robotic spray painting Line Main Systems

1)Electrostatic& Flame pre-treatment booth :

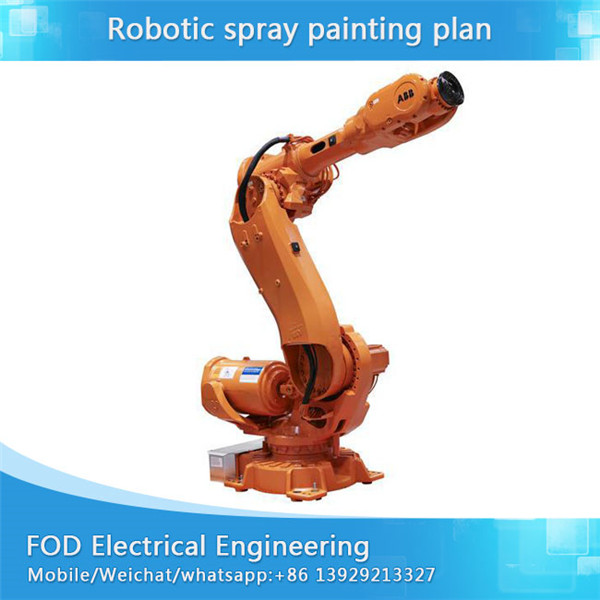

2)3Axis/4Axis/5Axis/6Axis Robot spray painting system

3)Devilbiss/Graco Automatic Spray gun

4)IR drying oven

5)UV curing oven

6)Chain Conveyor system

7) Air supplying unit

8) Graco Paint mixing& supply system

9)PLC touch screen control system

|

1,In put |

110V/220V/380/415V/440V,50HZ |

|

2,Output Power |

as per final design |

|

3,Max Spraying Area |

L3000mmX W1500mm |

|

4,No. Spray Gun |

1-4 PCS |

|

5, Spay coating type |

Robotic spray system |

|

6Spray robot structure |

5 Axis wrist rotation-145°~+145°, Max arm 1500mm. Body weight:110kg Acceptance inertia moment 0.2kgs.suqare m Install environment 0~40℃,20~80%RH |

|

7, Oven temperature |

0-150℃ adjustable |

|

8, Conveyor Speed |

0-6m/min adjustable |

|

9,Control Panel |

PLC touch screen |

|

10,Main Material |

Stainless steel & Steel |

|

11,Widely Application |

Wood panel, Laptop, display, LCD TV,Cellphone,MP3,Button,Desk computer Keyboard, Portable hard drive, Plastic ball, Car spare parts, Photo Frame, |

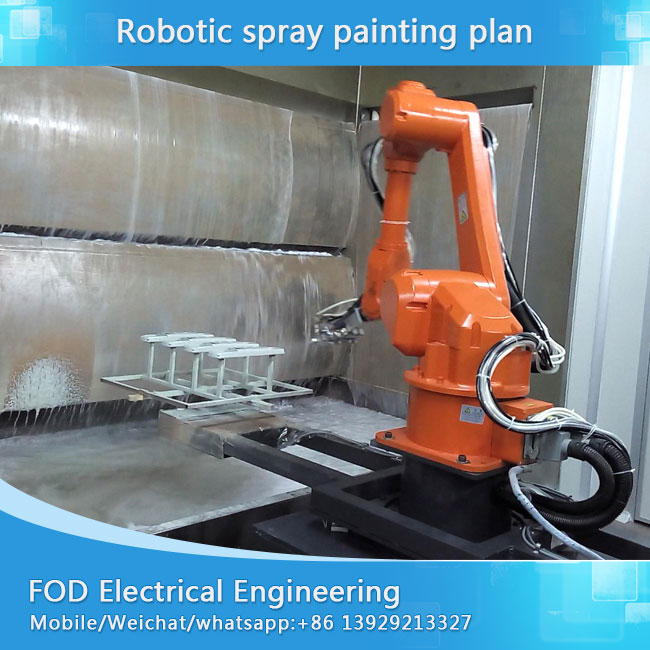

4.Robotic spray painting Line Picture Show

4.1 Robot Spray system

Automobile Bumper

4.2 Ground rack conveyor system

4.3 Paint Drying & Curing oven

4.4 Paint mixing system

5.Maintenance Guarantee

One year warranty will be provided on the condition of normal operation of the machine. During the period of warranty, damaged parts could be exchanged at free if the damaged is owing to bad quality of the goods, Damaged parts is required to return us. If it was damaged by human being, parts will be exchanged or repaired at cost as quotation.

Engineer is available to oversea for installation,trainning and maintenance.

6.Fast Shipping

1.Deliery within 10working days.

2.FOB Shenzhen or CIF sea shipping.

3.Wooden case package avoiding damage

Product detail pictures:

Related Product Guide:

Need of Powder Coating Equipment

Using Conveyor Systems

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of Special Design for Frozen French Fries Production Line - Five year mainternance Robotic spray painting line for OU paint,UV paint spraying – FOD Electrical Eng , The product will supply to all over the world, such as: United Arab emirates, Berlin, Puerto Rico, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we give customized & personalised services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.